ERATZ Engineering

VeraCAD

A graphically interactive design software for reducer roll tools

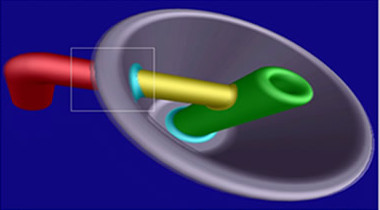

The use of VeraCAD in the forging industry significantly reduces design time for reducer roll tools and hence time to market. Based on the option to select automatic design on one hand and on other hand to provide input parameters interactively, the number of necessary rolling passes will be reduced and hence the tool-costs minimized.A precise volume calculation, the implementation of elementary design rules and consideration of the technology and procedure limits, will guarantee a coordinated and harmonized calibration sequence. This will avoid rolling defects at the final products and provides higher process stability.

Basic system

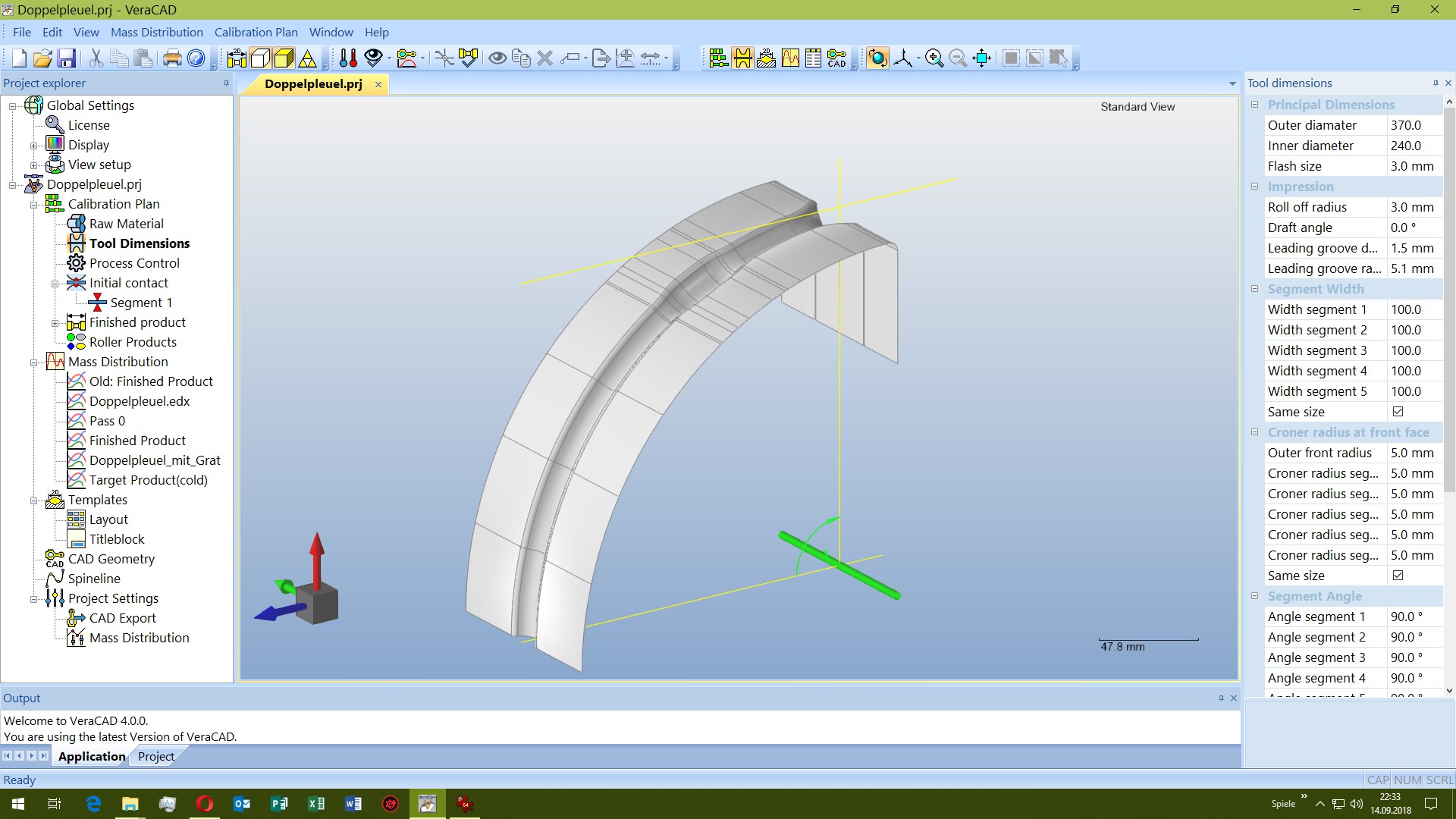

The basic system includes these modules:- Manual input, design and modification of the stretch roll finished product.

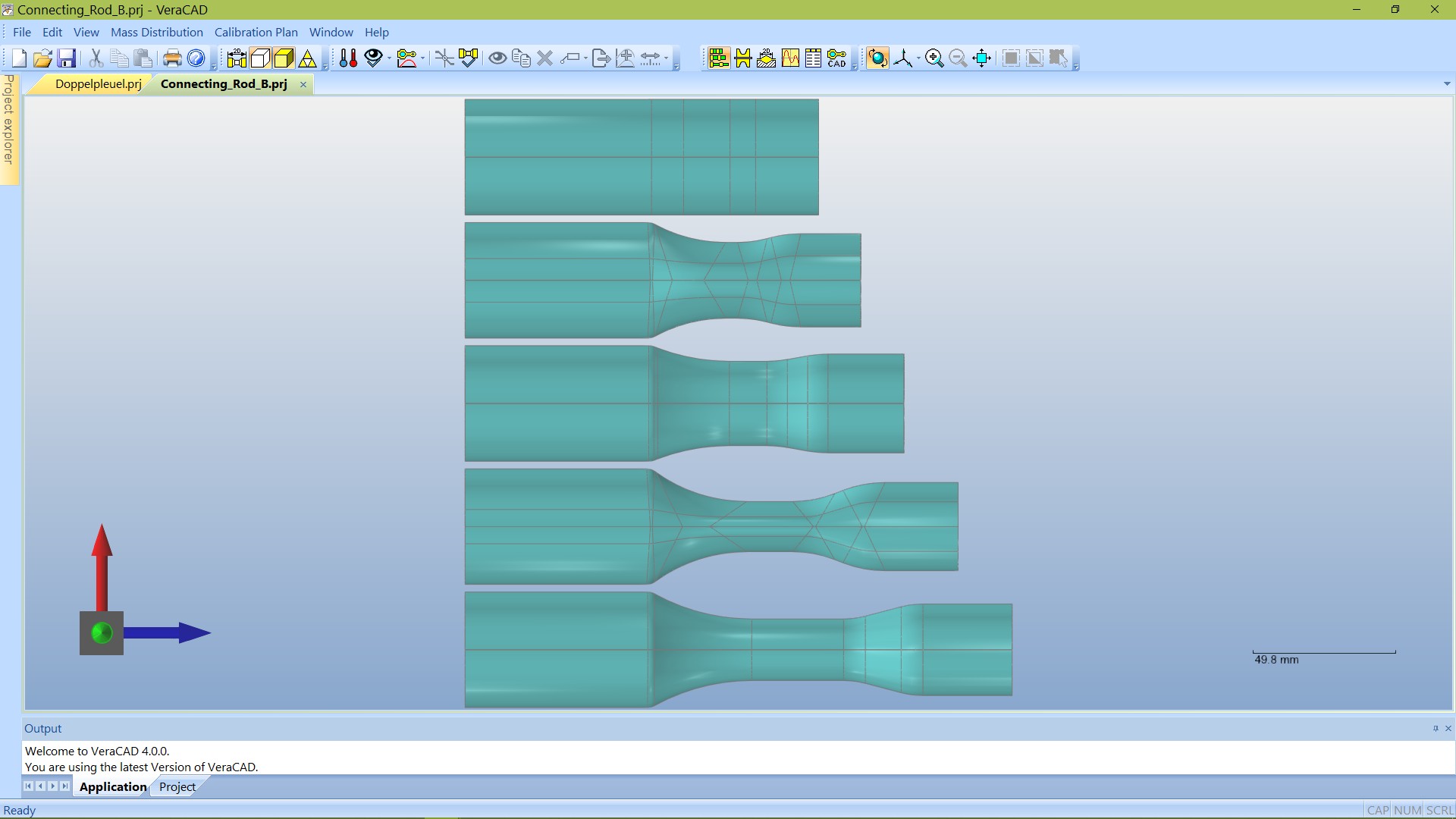

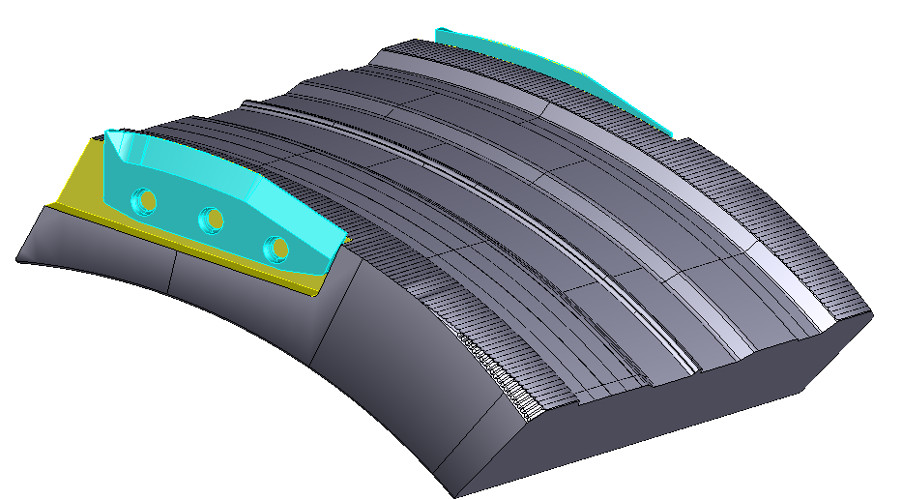

- Automatic calculation of the calibre plan with the number of stitches, stage sequences, geometry of the rolling intermediates.

- Graphical and tabular edition of the calibre plan and rolled products.

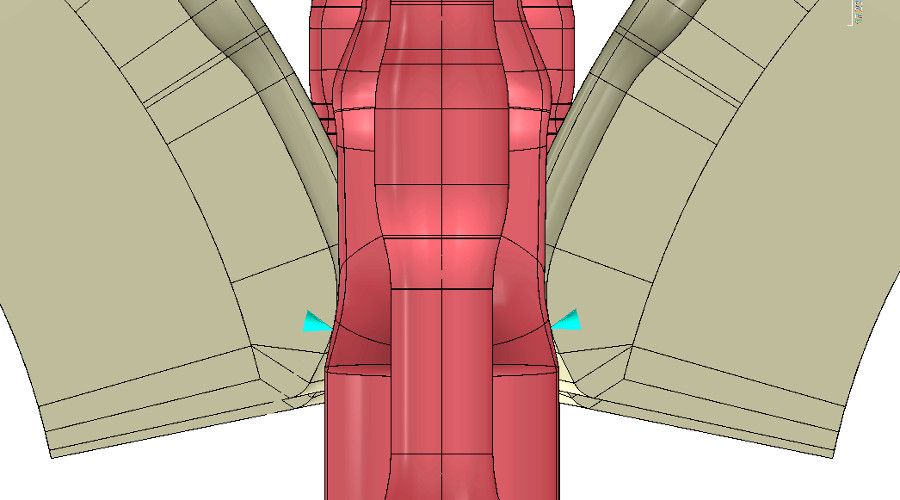

- Generation of 3D geometry for the tool engraving.

- Output of rolled products and stretch roll segments with common CAD interface formats (IGES, VDAFS, EDX).

- Stencil construction for the creation of technical drawings of rolling engravings. For each roll pass a drawing sheet is generated with a longitudinal section and cross sections including the dimension. The output is possible on plotters in various formats (up to A0) or for further processing via an IGES interface. The stencil construction is used for the manual production of the rolling segments or in conjunction with CAD / CNC milling for quality control.

- Project management.

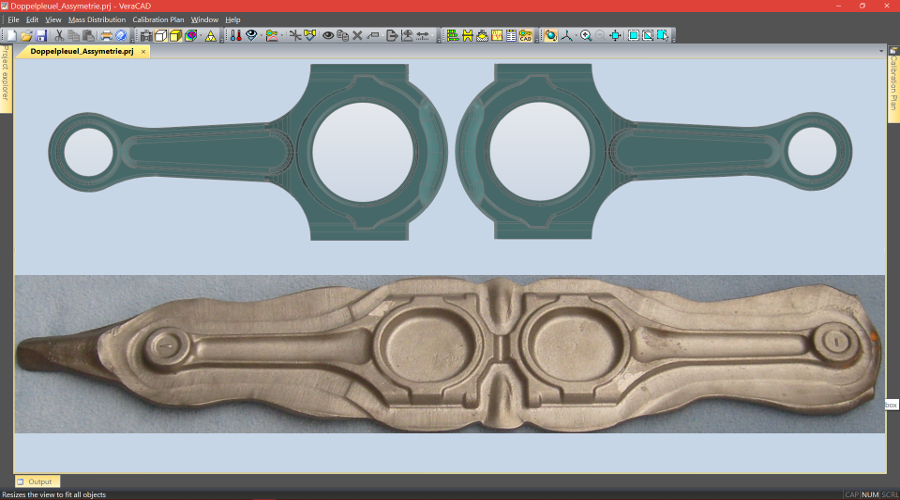

Module mass distribution

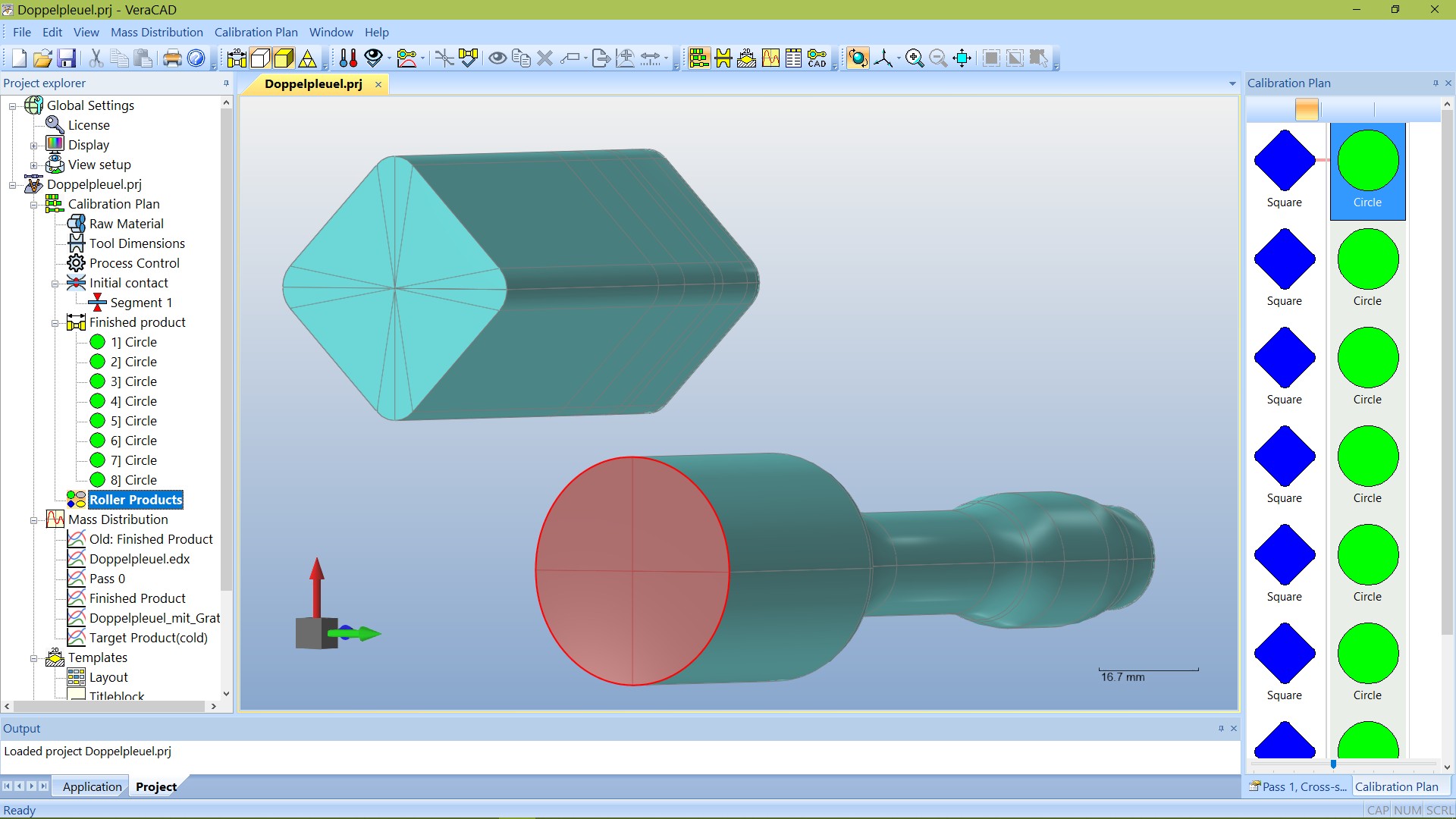

VeraCAD includes the functions for creating and editing mass distributions:- Importing complex CAD geometries such as connecting rods, crankshafts, etc. via various interface formats (IGES, VDAFS, STL, EDX).

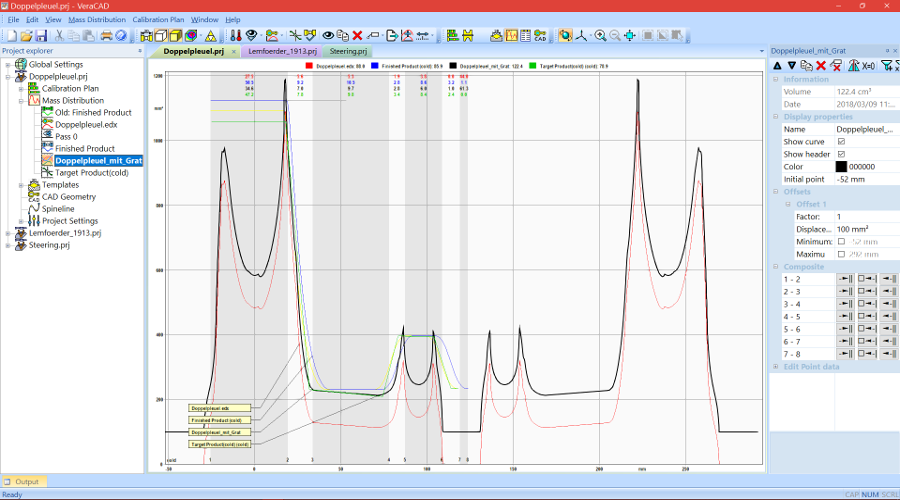

- Create mass distribution diagrams from external programs.

- Graphically interactive manipulation of mass distribution (e.g.Spine proportion)

- Automatic generation of the geometry for the finished product due to the mass distribution.

Module 2d-drawing

- With the menu "2d-drawing" the technical drawings of the rolling segment engraving are created and printed out on sheet formats up to DIN A0 or export via an IGES interface.

Please contact one of our partners for your area. We will send you an individial offer.

Pictures

Screenshots

Saving material with VeraCAD

Menu

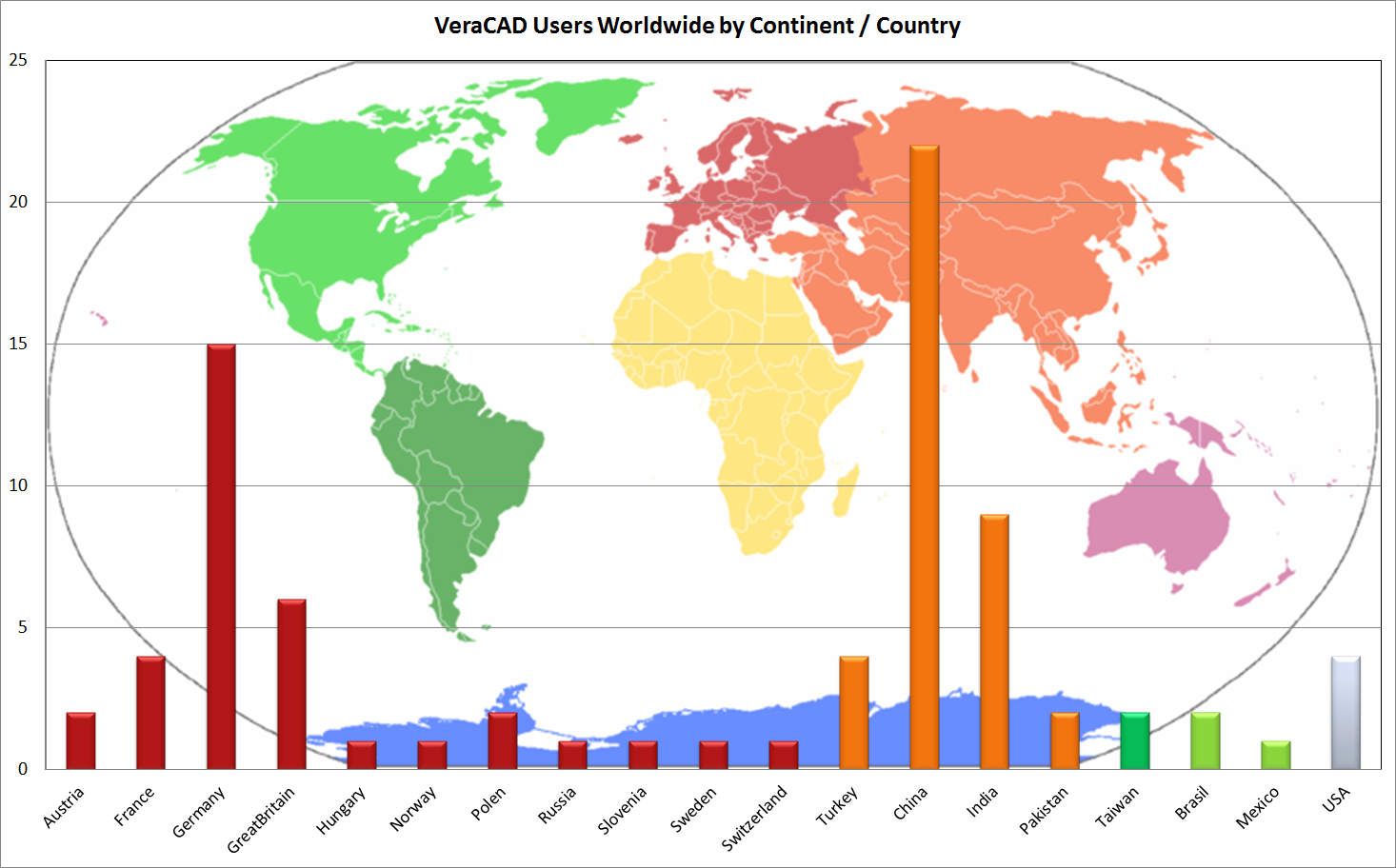

References

Germany- Bharat Forge Aluminiumtechnik GmbH Brand-Erbisdorf

- Daimler AG

- Frauenthal Powertrain GmbH

- Erdmann Unternehmensgruppe Hammerwerk Haspe

- Frauenthal Powertrain GmbH

- Hirschvogel Automotive Group

- KMS Gesenkschmiede Deutschland

- Otto Fuchs Metallwerke GmbH

- Schmiedetechnik Plettenberg GmbH & CO.KG

- PSW Schmiedewerk GmbH

- SCHMIEDAG GmbH

- Schöneweiss & Co. GmbH

- Schürfeld GmbH

- Schuler Pressen GmbH

- SMS group

- Thyssen Krupp Gerlach GmbH

- Baicheng Zhong Yi Precise Forgings (VRC)

- Bharat Forge Limited (IND)

- Bharat Forge Kilsta (SWE)

- Dana Spicer Europe Ltd (GB)

- DANA INDUSTRIAS LTDA (BRA)

- Dandong WuYiba (VRC)

- Dong Feng Motor Cooperation (VRC)

- Forges de Courcelles (FRA)

- FORJA de Monterrey (Mex)

- Happy Forging (IND)

- IMATRA Scottish Stamping (GB)

- IMATRA Tooling AB (SWE)

- John Stokes Forgings Ltd. (GB)

- Kongsberg Automotive (NOR)

- Mannan Shahid Forgings Ltd. (PK)

- Mahindra CIE Automotive Ltd. (IND)

- MMForgings Ltd. (IND)

- Pankl Schmiedetechnik GmbH (A)

- Peddinhaus Modern Technologies, LLC (USA)

- PSA Peugeot Citroën (FRA)

- PUNCH Precision Detva S.R.O (SVK)

- Rába Vehicle Ltd (Hungary)

- Ramkrishna Forgings (IND)

- Sansera (IND)

- Setforge Estamforge - Farina Group (FRA)

- Strojmetal Aluminium Forging s.r.o. (CZE)

- Thyssen Krupp Brazil (Bra)

- Thyssen Krupp Crankshaft Company (USA)

- Thyssen Krupp Mexiko (MEX)

- UEF Automotive Neptune Works (GB)

- University of Ulsan (KOR)

- UNIOR (SLO)

- Walor Bogny - UTAC (FRA)

- Zimmer GmbH (CHE)

Software

More

Imprint

ERATZ EngineeringHerrmann Eratz

Kirchhörder Str. 94

44229 Dortmund

Germany

Phone +49 (0)231 72 73 290

Fax +49 (0)231 72 73 291

E-Mail: he@eratz.de

© ERATZ Engineering